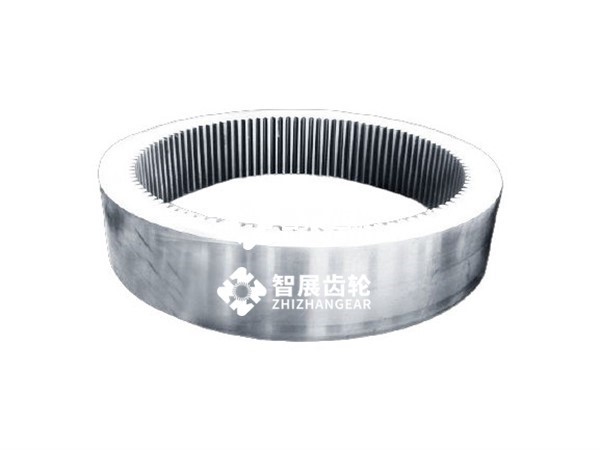

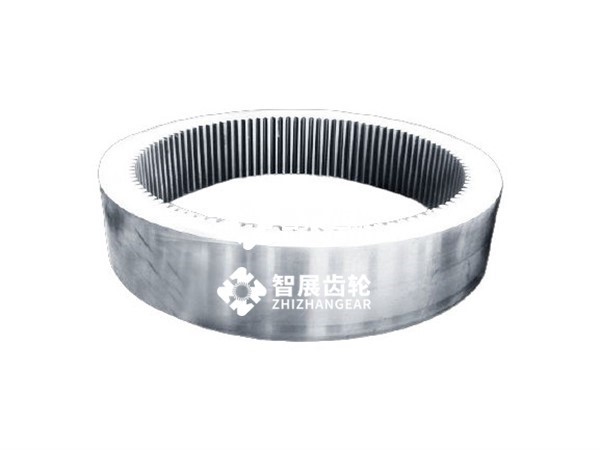

——The products are widely used in such fields as wind power, cement, oil drilling, shipping, thermal power, coal, mining, metallurgy, transportation, engineering machinery, water conservancy hubs, and aerospace.

——The precision of the products meets international standards, and some parameters even exceed the international level. The comprehensive precision of spiral bevel gears reaches DIN Class 5, and the precision of conventional gears reaches DIN Class 3. The positional tolerance of the box pin holes is less than 0.03mm (for 50 pin holes on a 2000mm reference circle).

——Types of spiral bevel gears: Klingelnberg and Gleason. The outer diameter of large gears is 2 meters, with no restriction on the module. Gears can be optimized to improve bending and contact strength. Tooth surface hardness: HRC 58-62; Precision: 5-DIN 3965.

——The products have a large range of overall dimensions. The diameter of hard-tooth-surface spiral bevel gears can reach 2000mm, and the diameter of conventional gears is 2000mm. There is no restriction on the gear module. The swing diameter of the box is 3000mm, and the height is 2500mm.